27 November 2025

Things are getting an awful lot tidier as I now have places TO put things as I sort them. The loft floor is getting a little cluttered, but I can target a number of things as I pull everything together that should be together. Things like all the spares for the 3D printer are now in one place ... and labelled.

Think this will complete my Yare Dragon collection. Auction costs and shipping was more than the actual lot, but driving down to collect would have been as much as shipping. Will have to be a special figure for me to bid next time.

Been delayed a bit, but I have the first set of marble run modules complete and actually working. The bees wax is still not the right consistency, but is better than candle wax. I possibly need something to liquefy it when working on the next lift, but other kit to work on first. I have a nice 30 second video of it actually running, but need to fix the web stuff so it's displayed properly. The old method of handling them no longer works, so something else on the TODO list.

All the bits have rolled up and the 3D printer is back together. I've even tidied all the cables although there is still a little work to do on the back right leg to replace the remaining masking tape. All of the ready made motor cables that I purchased had to be re-jigged to remove a peculiar twist in them. Putting back to straight through fixed it. In addition, the fan modules were wired with the power reversed, but only one was used as is and a quick swap around on that meant I could simply plug it in. The other fans needed to be wired to the long cables heading to the extruder head, so the plugs were removed.

Things are working a lot better with a 24 volt supply. There was a little confusion initially because I still could not get the Z axis to 'lift'. Going down was fine, but back up kept stalling. I thought initially it was the load from the extra pulleys and belt that locks the two sides together, which it was but only because I had not left a gap between the pulley and the motor body. Having freed them everything ran fine, but tightening one restored the problem. Drop the steel ruler under THEN tighten, and everything was fine. Since THIS was the problem that caused me to go all in on the 24V refit, I may well have jumped the gun a bit, but the extruder heat-up time is now excellent, and I don't think ABS will be a problem.

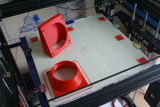

I've run a second pair of fan housing for the laser cutter fume extract and the surface finish is very good. All that I still need to do is get a little more tension in the X and Y belts as the adjustment on the motors is at it's limit, but I think even as is I'm happy to run the parts for one of the Gambody models. Starting point will be the section of Liberator body I've already printed but which has random 'noise' in the surface layers, as does the first fan hood. But lets print an extra tensioner prior to committing to that 36 hour print.

Perhaps not the best place for a lathe, but the dust from drilling the chipboard base is easier to clear up than on the carpet. Another reason for needing to finish the floor in the loft area. The motor inverter still need securing, but the lathe is working and I can now at least get the red 7x0.2mm wire sorted out. I've got a 500mt reel, but need to transfer 100 to the smaller reels that match the rest of the 7x0.2mm range. When the 1.5mm MDF finally rolls up I can make some smaller reels for the 32x0.2mm set which will be tidier, but I do have an annoying problem in that the 14x0.2mm wire only has some odd colours left. None of the normal colour set seem to be around. The reels I do have are a lot heavier cover than the normal equipment wire, almost the same as the 32x0.2mm stuff so I may need to spend money to replace the colours I do normally use ... which I think can wait as I do have enough offcuts to build a few more Divisionmasters at least.